In the global edible oil industry, consistent quality and operational efficiency are no longer optional—they’re mandatory. For producers handling up to 2,000 tons per hour, integrating an intelligent control system compliant with ISO9001:2000 isn’t just a technical upgrade—it’s a strategic imperative.

A typical large-scale peanut oil press operates under variable conditions—temperature swings, humidity fluctuations, and inconsistent raw material input. Without real-time monitoring and adaptive controls, production stability drops by as much as 18–25% annually (source: FAO Food Processing Report 2023).

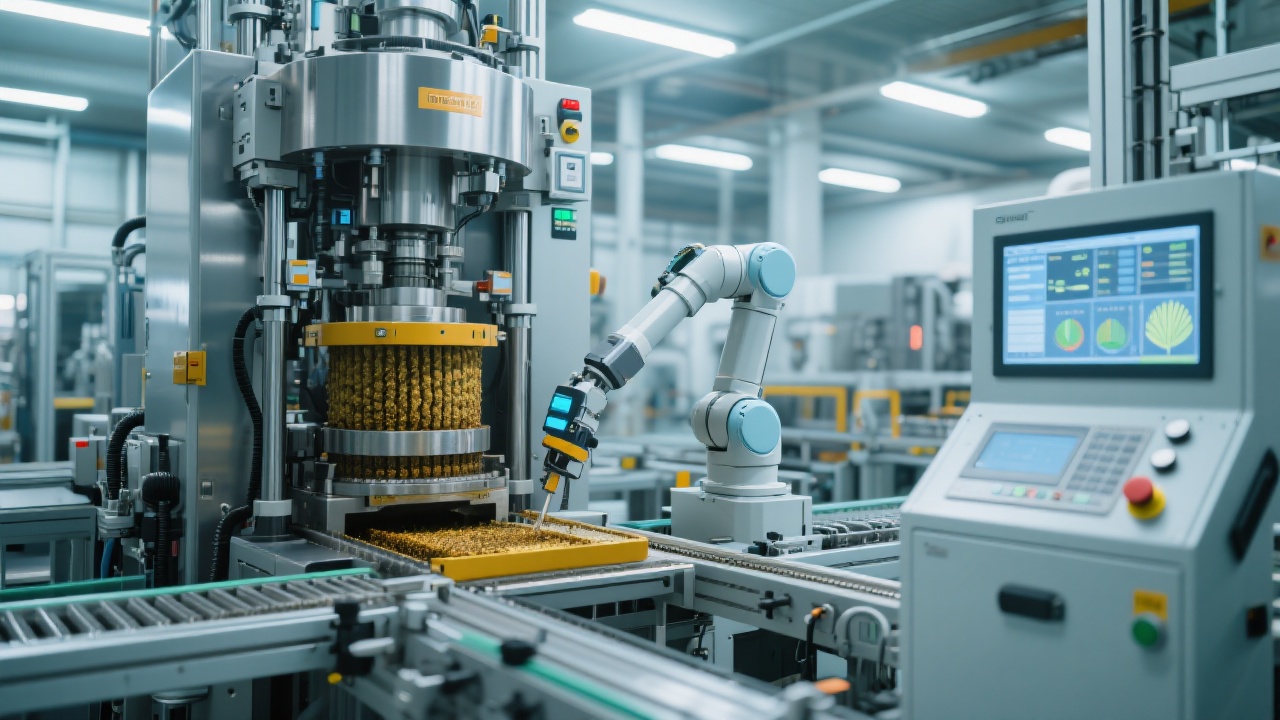

Our smart control solution integrates hardware sensors, PLC-based logic controllers, and cloud-connected dashboards to ensure every stage—from oil extraction to filtration—is optimized for both yield and consistency. This system reduces energy consumption by up to 12% while maintaining product purity within ±0.3% moisture content—critical for meeting international food safety standards.

| Feature | Benefit |

|---|---|

| Real-Time Data Monitoring | Reduces downtime by 30% through early anomaly detection |

| Fault Diagnosis Algorithm | Cuts repair time from 48 hrs to under 12 hrs on average |

| Remote Maintenance Interface | Enables 70% of issues to be resolved without on-site engineers |

We’ve deployed this system across over 30 facilities in Africa and Southeast Asia—including a 2,000-ton/hour facility in Ghana that saw a 15% increase in monthly output after implementation. In Indonesia, another client reported a 22% drop in maintenance costs due to predictive diagnostics.

These results aren’t isolated. They reflect how modern control systems bridge the gap between traditional manual operations and Industry 4.0-ready manufacturing—especially where skilled labor is limited and environmental variability is high.

The integration of smart control into peanut oil processing isn’t just about technology—it’s about building trust with buyers, regulators, and end consumers who demand transparency, traceability, and reliability.

Get a tailored configuration plan for your facility—including compatibility checks, installation timelines, and remote support options.

Explore Smart Control System Configurations Now